Toyota Vehicle Speed Control

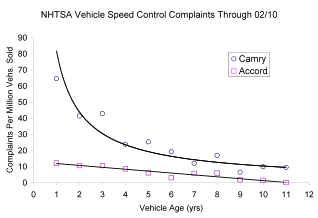

Figure 1. Vehicle speed control system reliability analysis results. |

Beginning in 2000, many auto manufacturers started changing their vehicle speed control systems from a linkage and cable type assembly, with a mechanical connection between the accelerator pedal and the throttle body, to a completely electronic system. The new designs include electrical sensors, wiring, a computer, and a drive motor – so called “fly by wire.” For Toyota, this change started with their 2002 model year.

Because of the recent press surrounding Toyota vehicles with sudden unintended vehicle acceleration, Duffner Engineering conducted its own independent reliability analysis of the Toyota vehicle speed control system. For our analysis we chose the Toyota Camry, and for comparison, we chose the Honda Accord, which also has an electronic vehicle speed control system, but of a different design and manufacture. The failure data for the two vehicles was taken from the National Highway Traffic Safety Administration (NHTSA) website. Duffner Engineering reviewed more than 1000 vehicle speed control complaints for the Camry and Accord from 2000 to 2010. Over this period, the Camry exhibited a nearly four times higher failure rate of the vehicle speed control system compared to the Accord.

The results of our reliability analysis are shown in Figure 1. The vehicle speed control system on the Camry appears to be suffering from a decreasing failure rate. The curve for the Camry shows a significant decrease in failures after the vehicle’s first three years of service. This is typical of what is termed an “infant mortality” problem with the product, as opposed to random failures, such as exhibited by the curve for the Accord which shows a nearly constant failure rate, or wear out, which would appear as an increasing failure rate.

The cause of infant mortality behavior in the failure rate of a product is typically associated with a manufacturing defect. Such defects can usually be isolated with detailed examination and testing of the component parts of a few of the failed products, and comparison to products in the population which have not suffered failures. To date, we are unaware of any such examination, testing, and comparison.